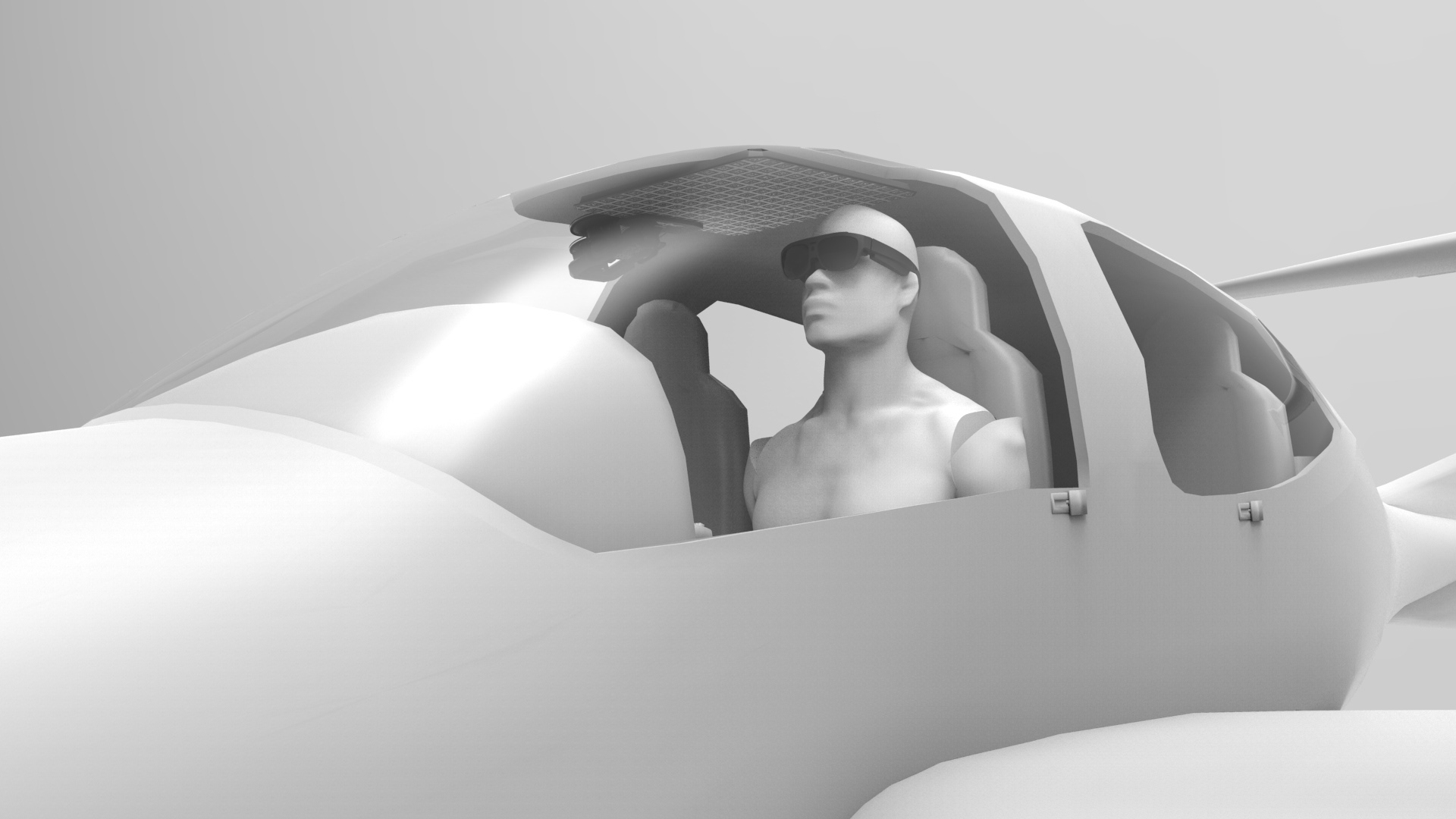

Aero Glass is a San Diego based company developing an unparalleled 360° 3D Augmented Reality navigation experience using Smart Glasses addressing pilots' need to properly visualise terrain, navigation, traffic, weather, and airspace information with access to vital safety procedures and protocols, without the requirement of inspecting instruments, regardless of the visibility.

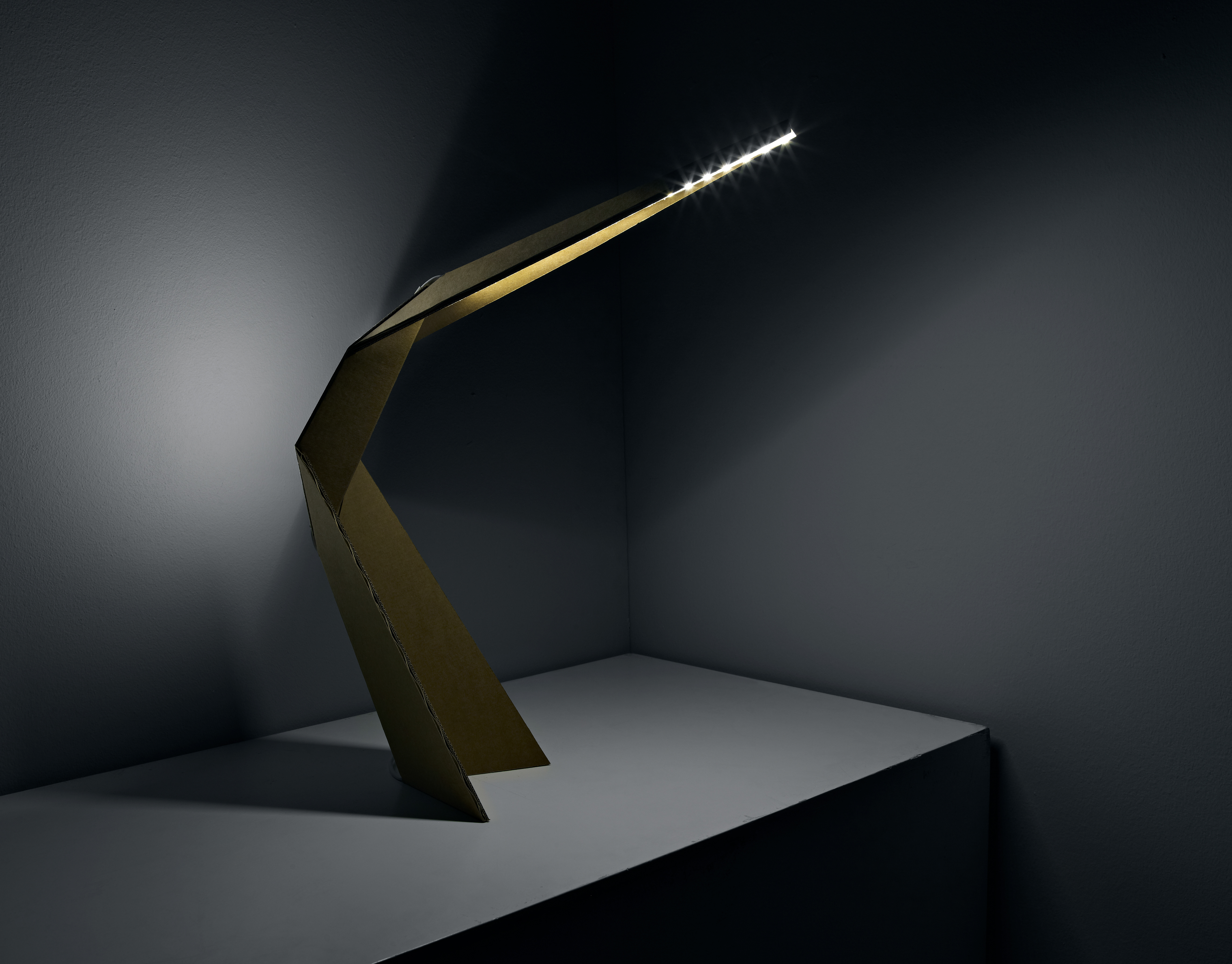

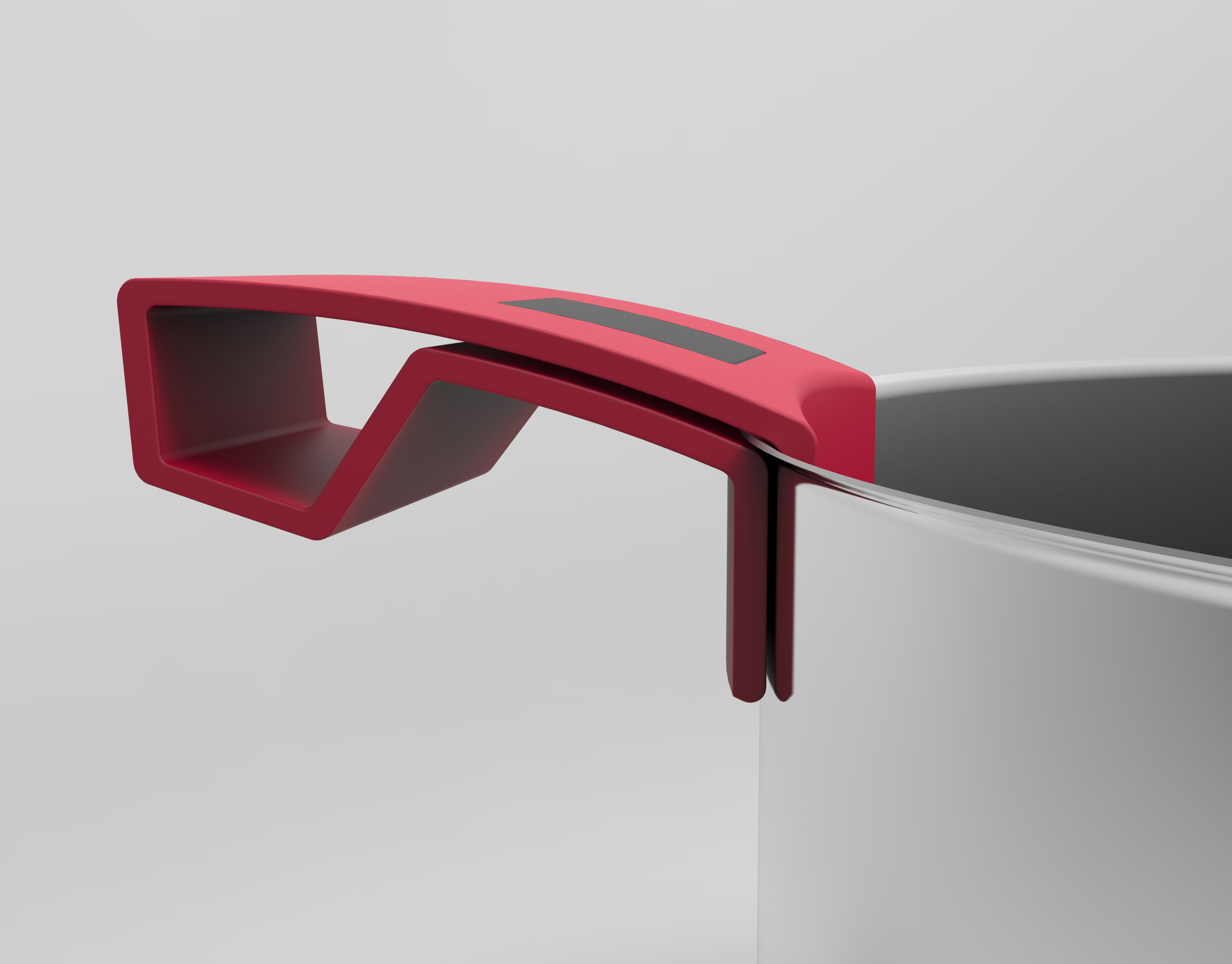

IgenDesign participated in AeroGlass' R&D project by developing their brand; improving the overall user experience of their products and designing physical products from design concept to production release.

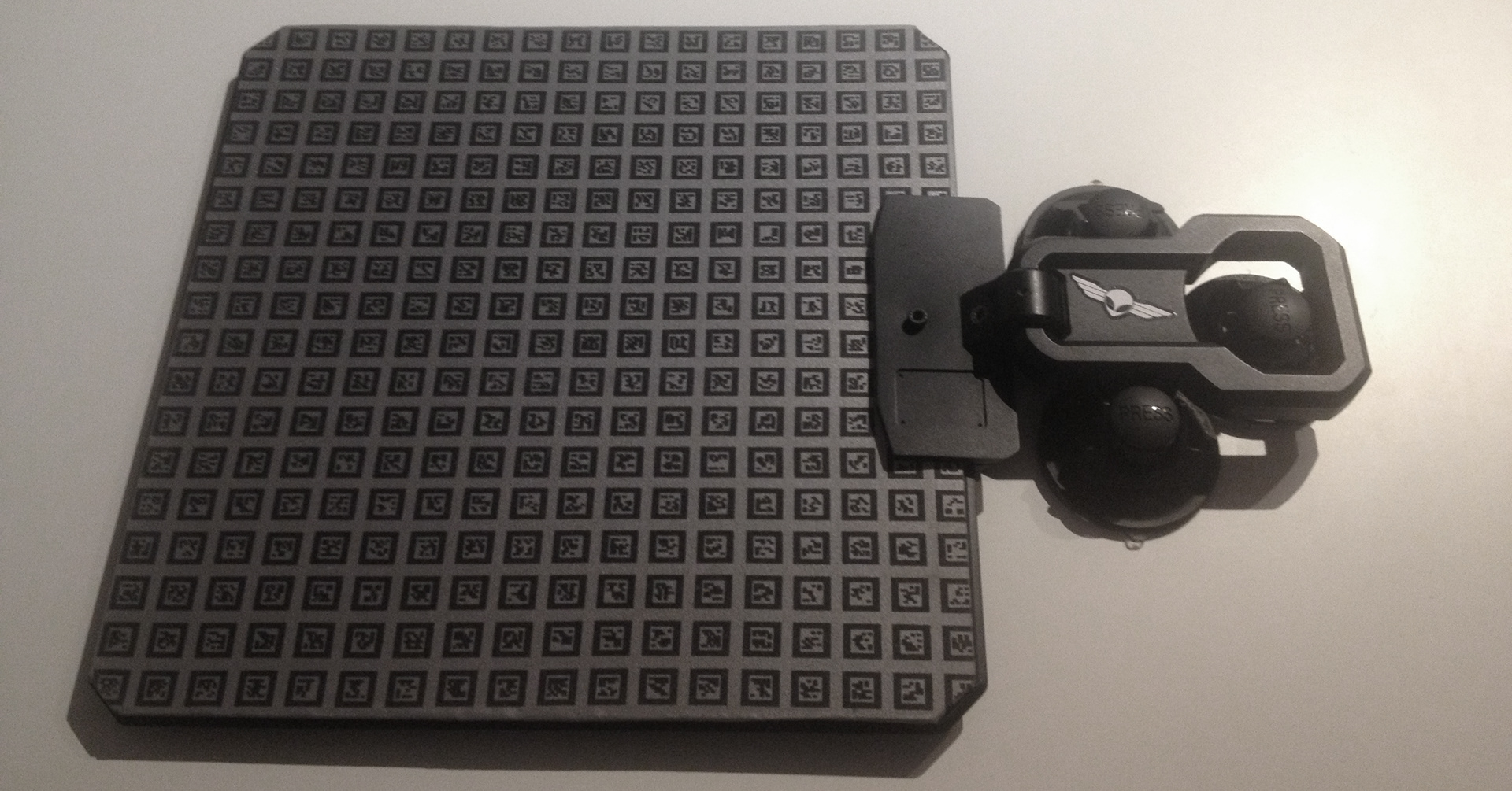

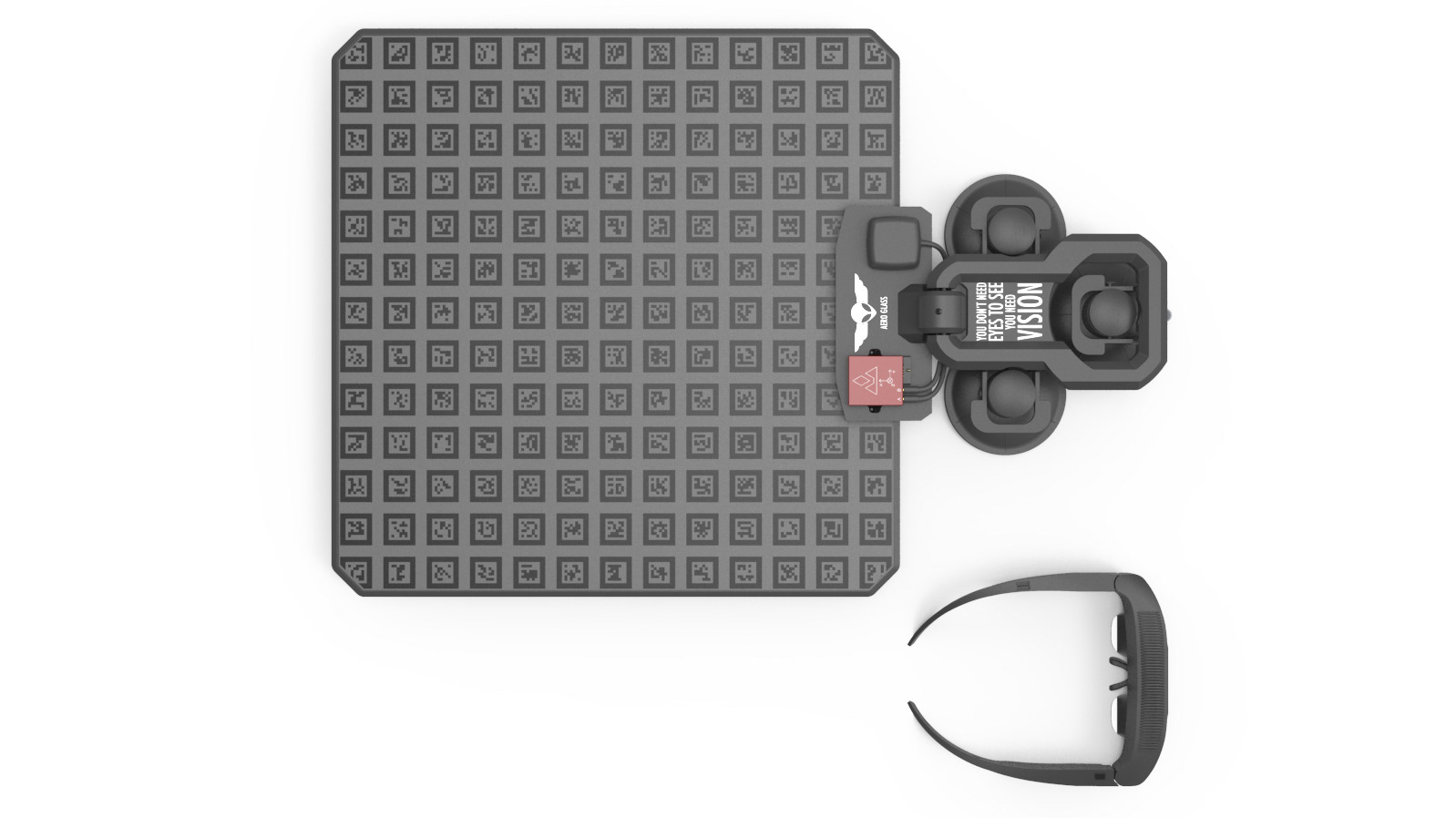

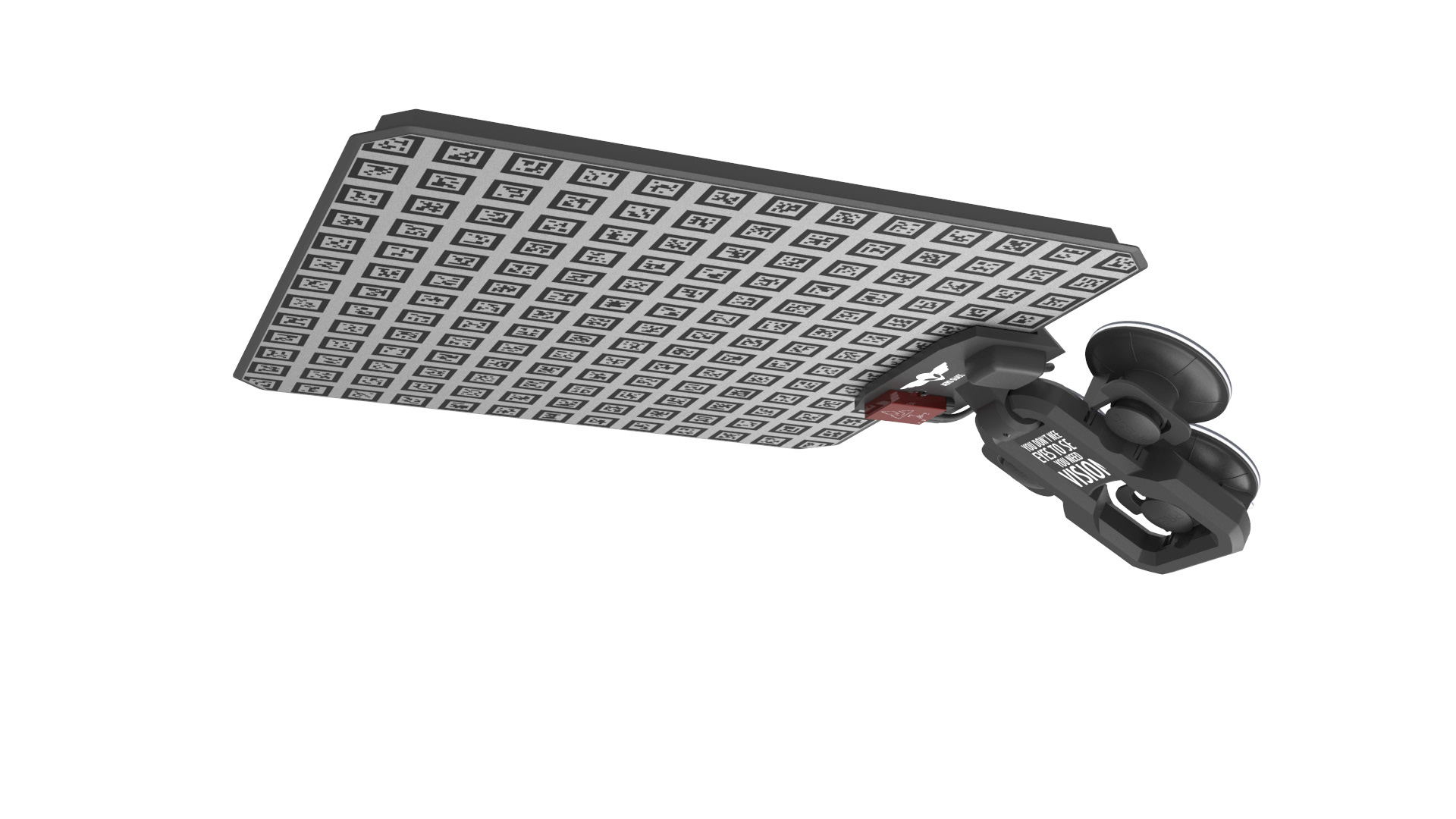

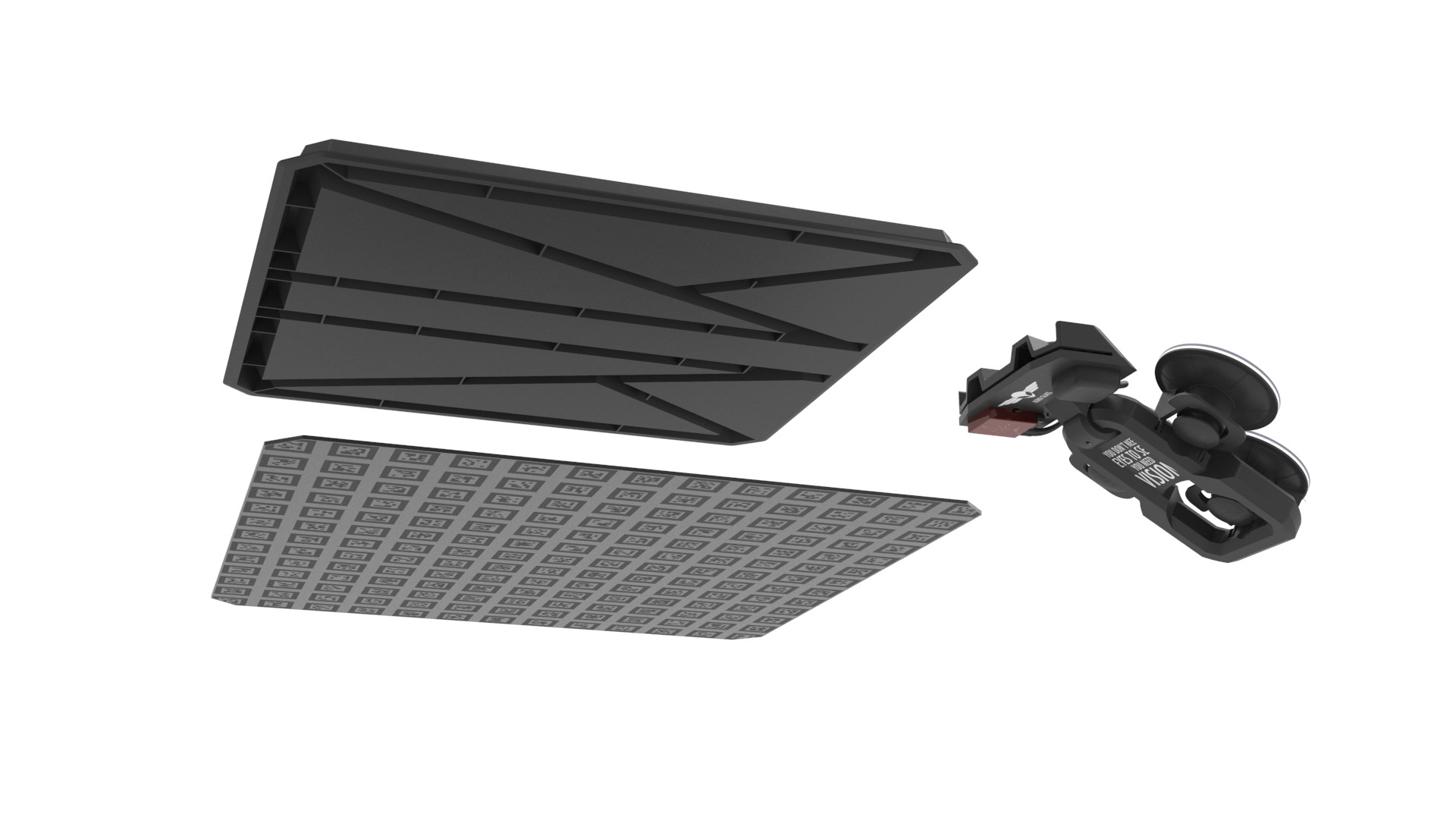

IgenDesign has developed the MarkerBoard for AeroGlass which has a key role in AeroGlass' High Precision Head Tracking Kit.

How custom head tracking works

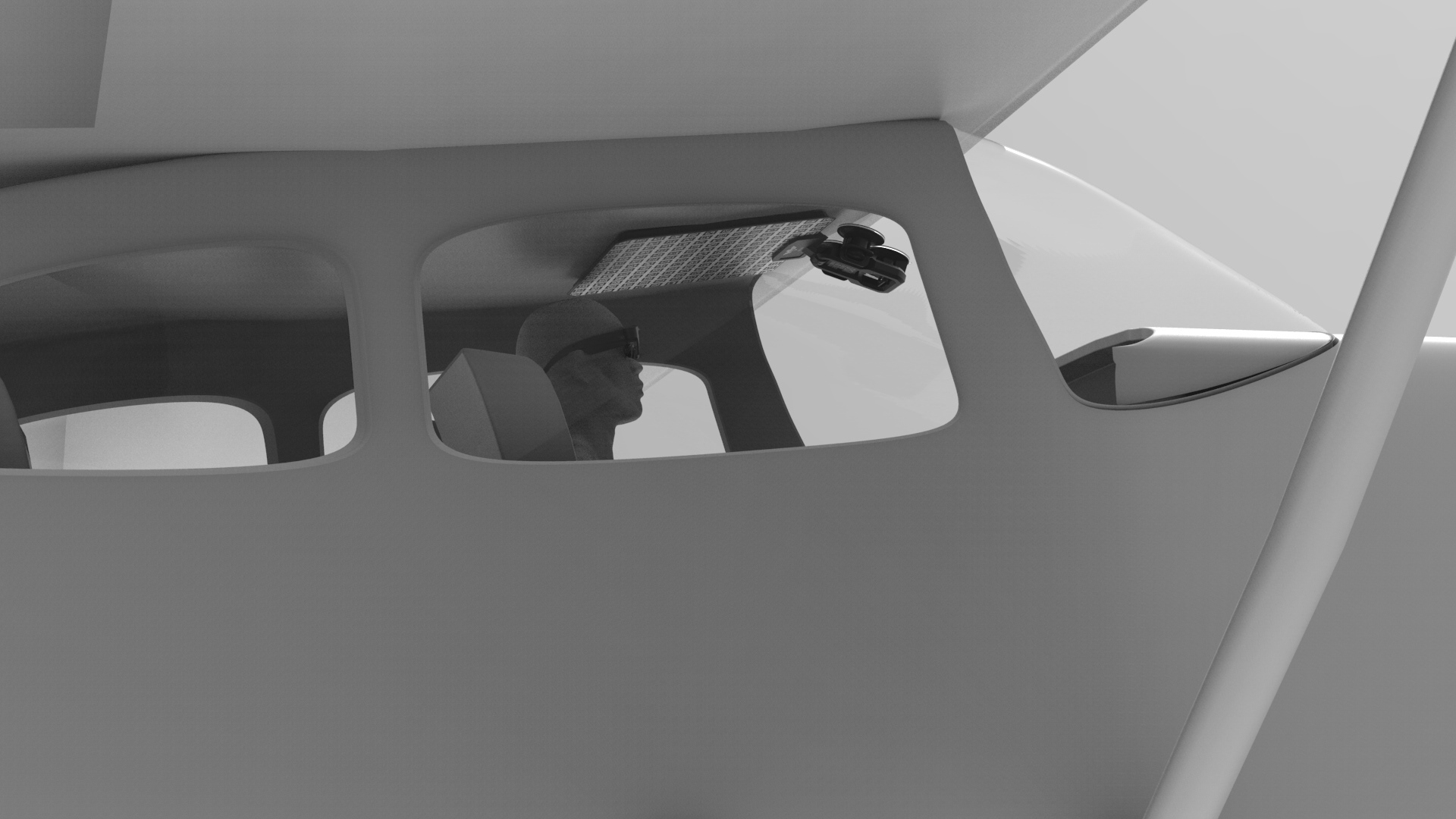

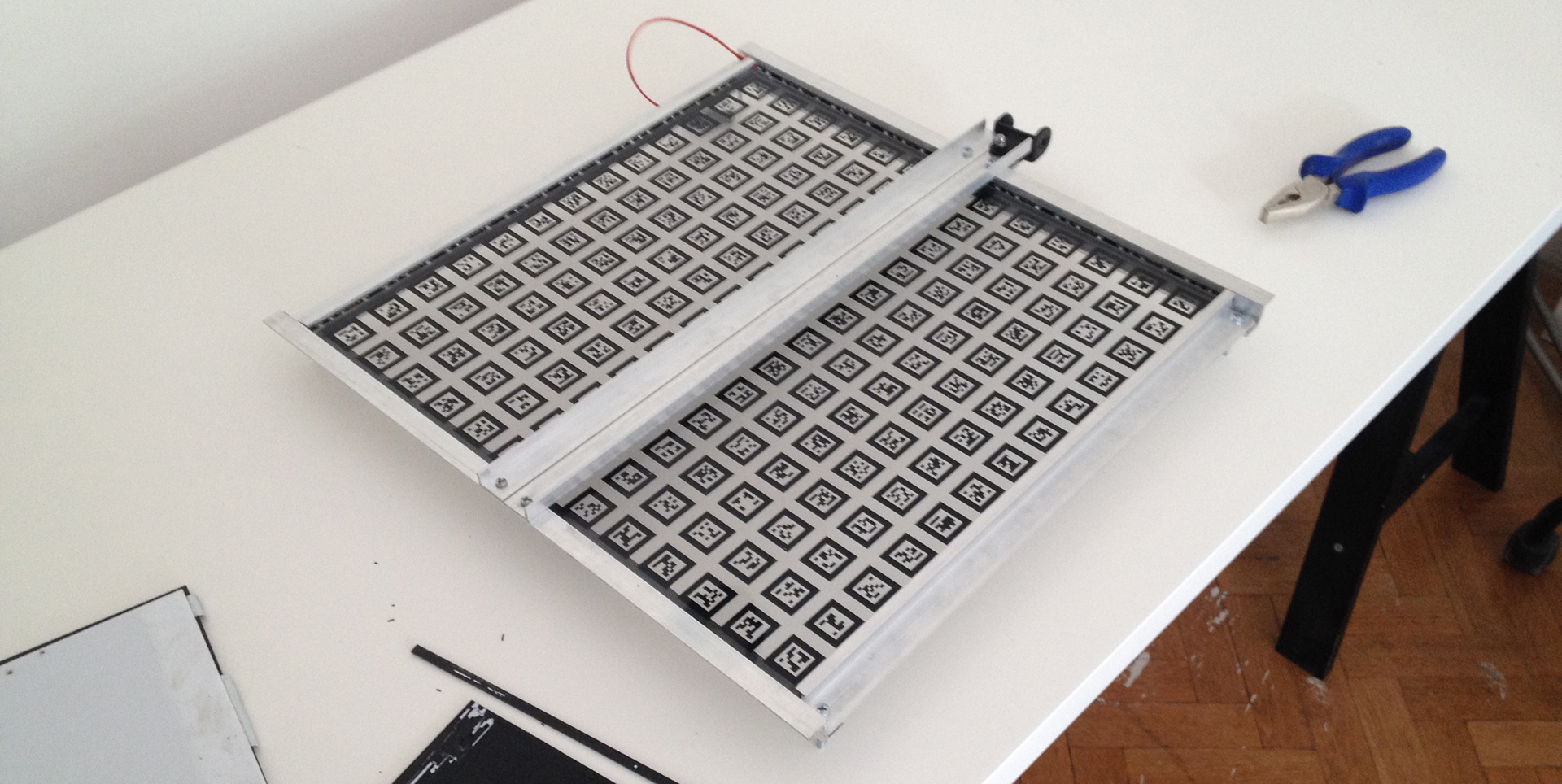

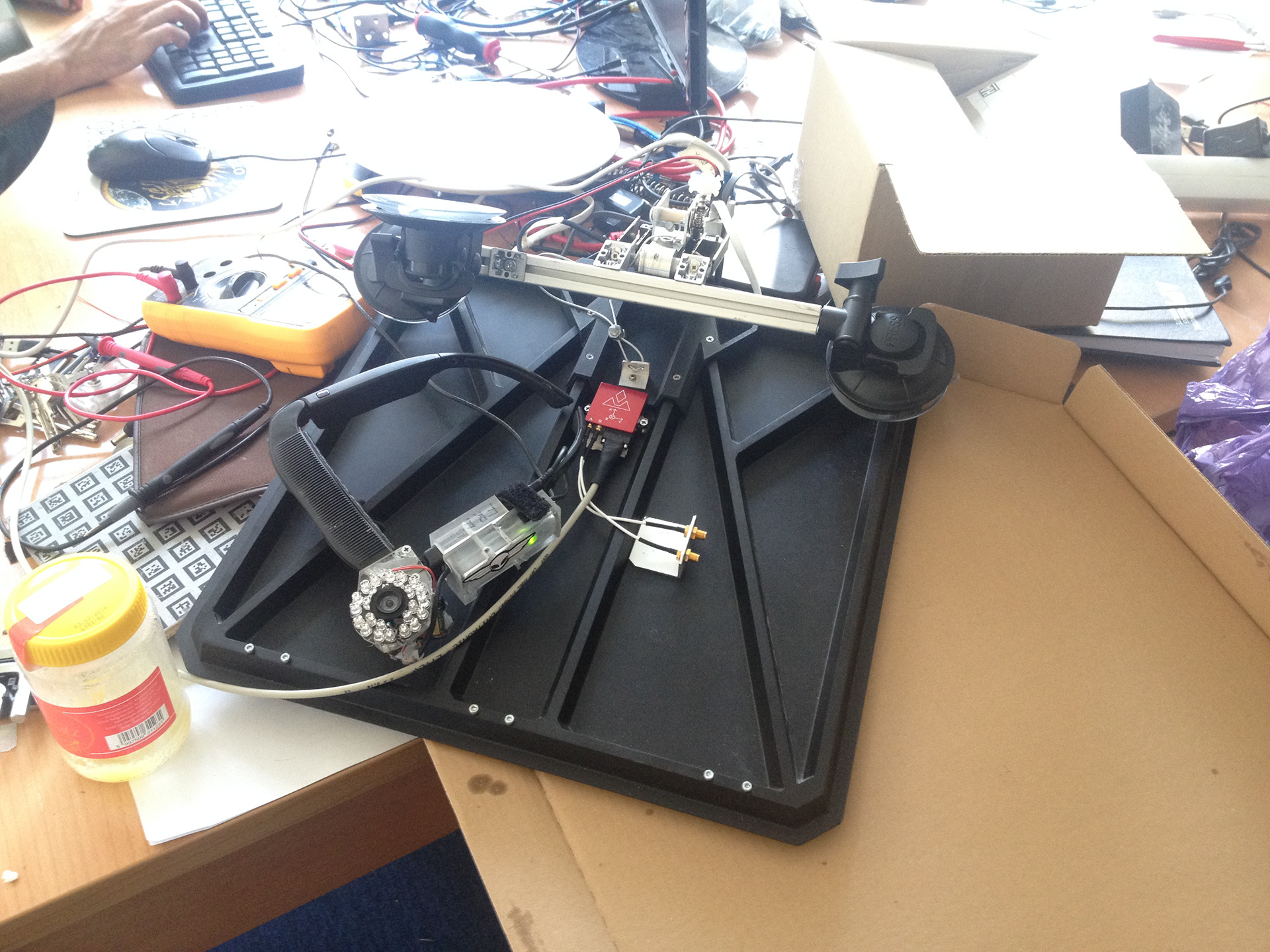

Accurate head tracking is necessary to be able to visualise all graphics in the right place in augmented reality navigation. Smart Glasses are tracking special, QR code like markers on the MarkerBoard with small cameras while the glasses' displays move and rotate with your head. Therefore the system enables an augmented reality overlay with a precision of 0.2° – 0.5° in a dynamic environment in a moving vehicle.

Actual experience through the smart glasses

The MarkerBoard's no.1 requirement was its high rigidity: markers on the board has to be kept 100% flat and still even at 3G vibration and at drastic air pressure decrease. On the other hand the MarkerBoard cannot be fixed permanently to the cockpit because of certification constraints. The Head Tracking Kit has to be fully portable and easy to frequently install and remove in any type of aircraft as most users rather rent than own his aircraft. MarkerBoard must fit into booth classic (Cessna style) and modern (full plexiglass) cockpits. Markers are lit with IR light and read with IR cameras, therefore special light reflecting material was used for the marker layer to enhance camera tracking.

IgenDesign has conducted through its engineering and manufacturing partners all stages of the MarkerBoard's product development covering ergonomic research, concept development, product design, engineering design, frugal prototyping, reliability testing, high accuracy prototyping, production release.

Behind the scenes: Building-Testing-Building-Testing…

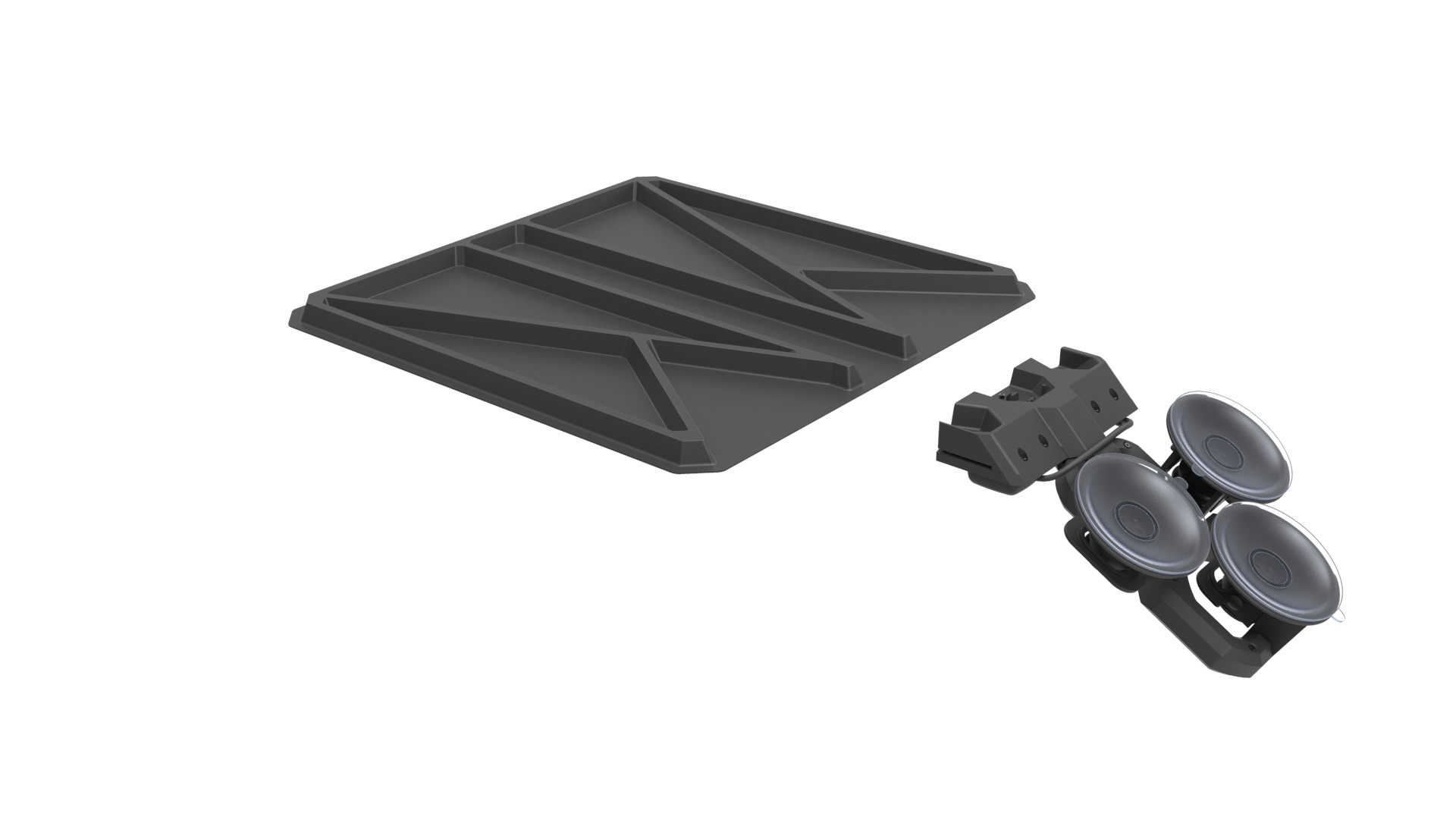

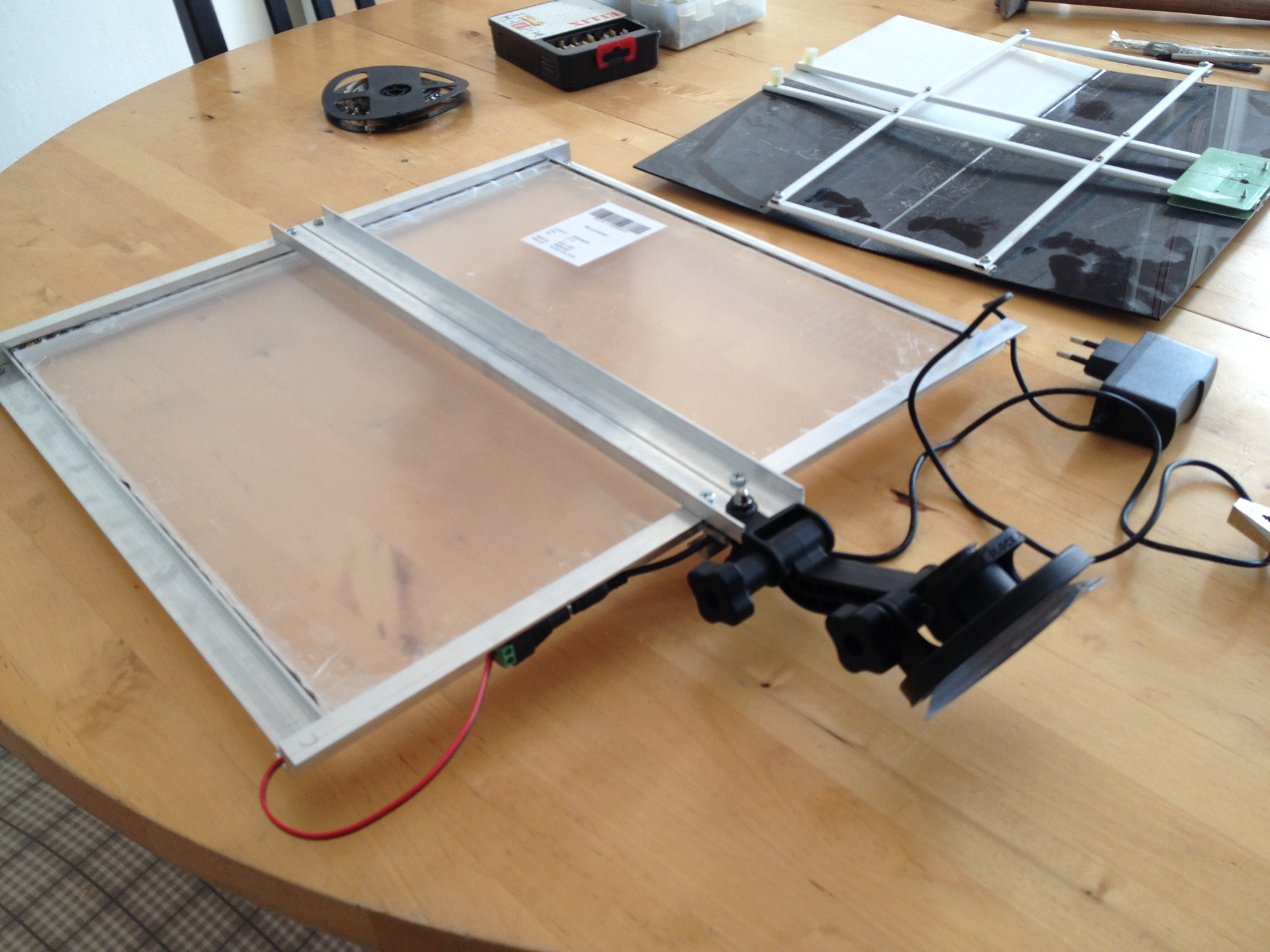

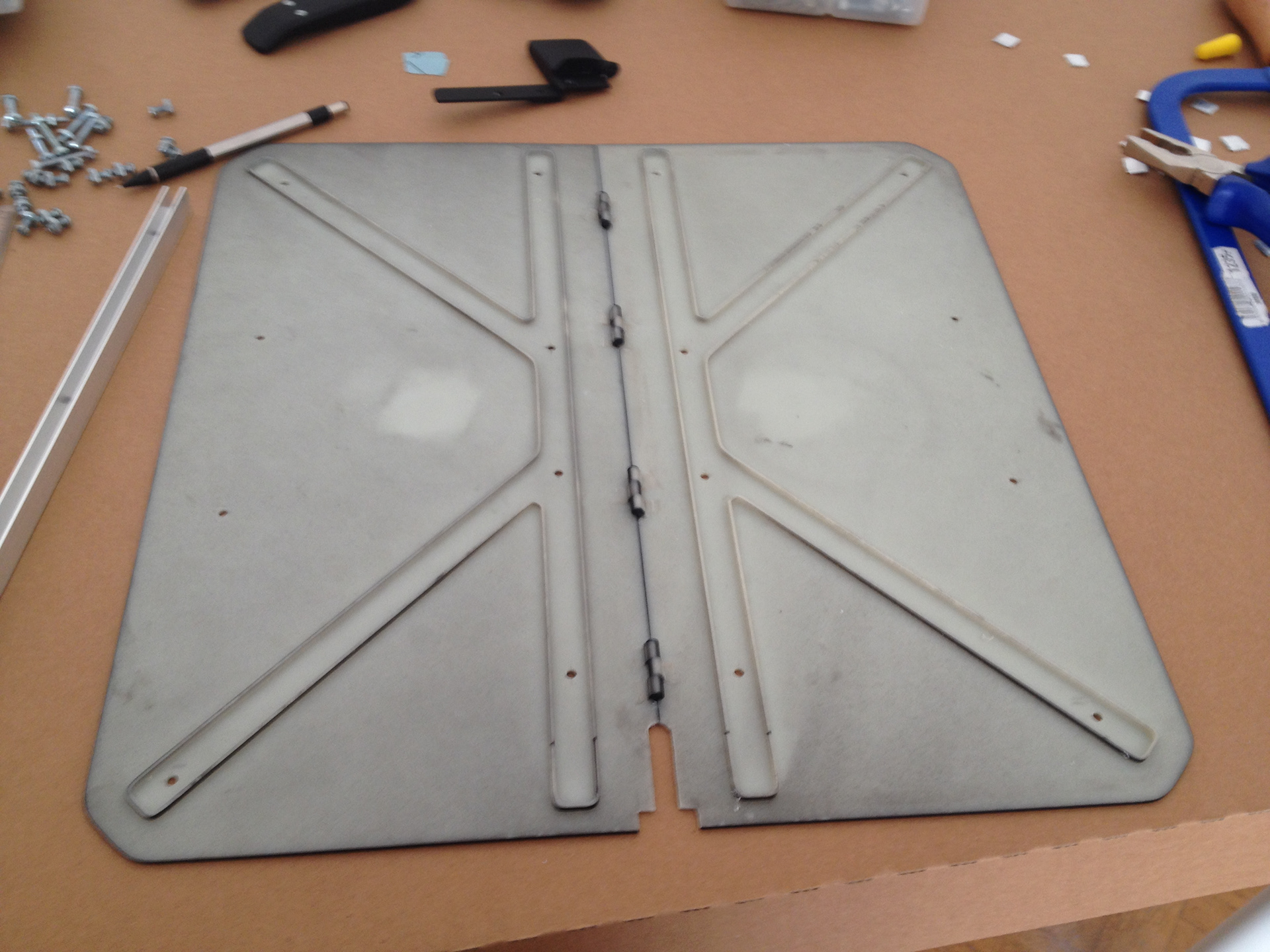

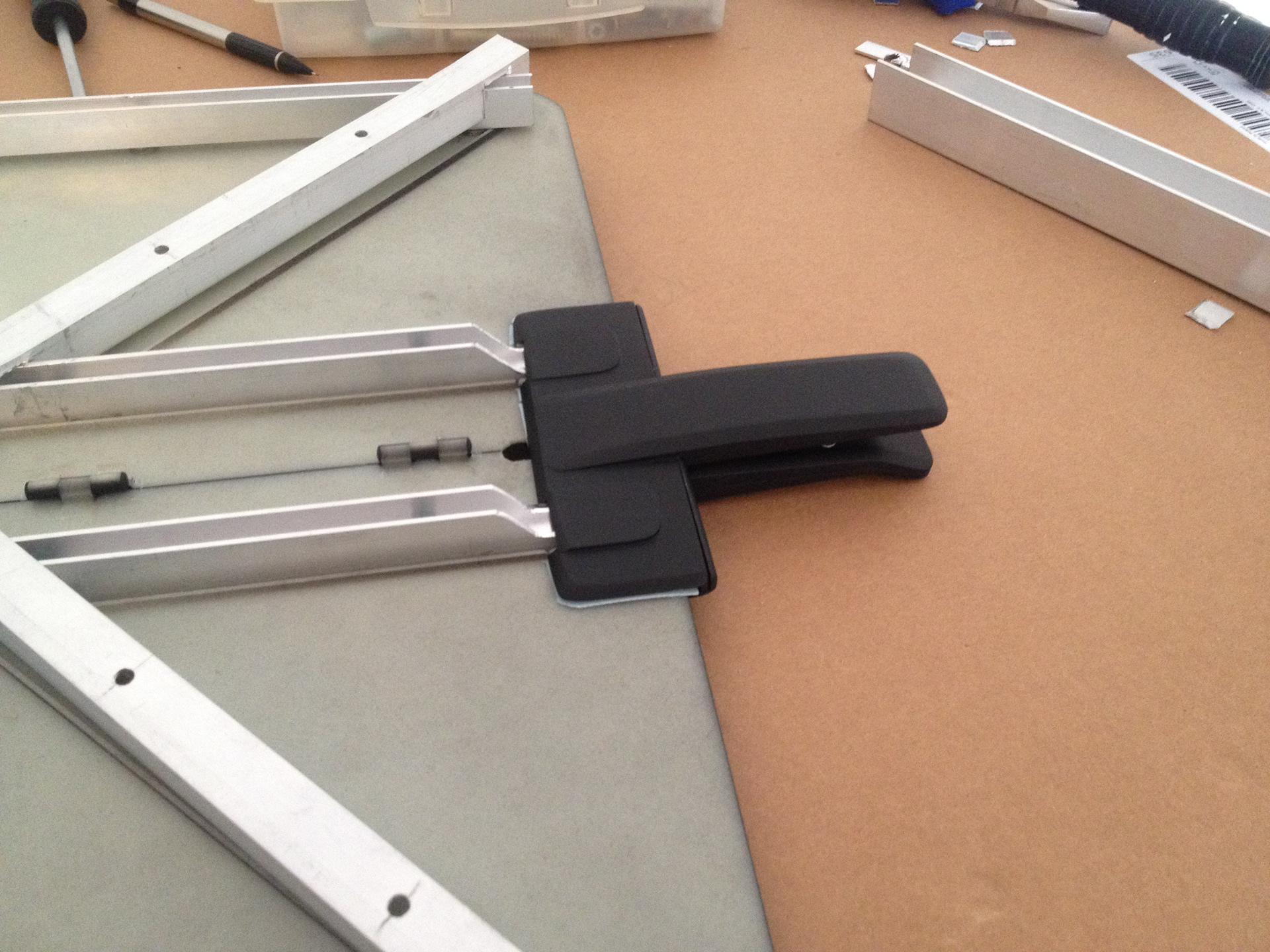

From super frugal to highly accurate models we built and tested several concepts and prototypes to explore bracing ribs geometry for the MarkerBoard and mounting options with vacuum cup layouts.

After developing on frugal level, high accuracy CNC milled prototypes were made of all parts to get injection moulding level precision and material behaviour for testing final geometry of the board and the vacuum cup mount.